Looking for any specific details? We DTY Services team here to answer.

Directing To You Services

Oil & Gas Engineering

DTY services is a emerging contractor that provides a one-stop comprehensive spectrum of specialized engineering solution services to suit the global Offshore industry.

— Oil and Gas Engineering Services

Since our inception in 2015, we've curated a team of seasoned professionals with diverse engineering expertise. Our robust capabilities enable us to offer cost-effective solutions without compromising on Quality and Safety. Through comprehensive assessments, we seamlessly integrate services as a Turnkey provider for yards, vessels, and owners. With an unwavering commitment to growth and customer satisfaction, we continuously seek new opportunities to lead the market forward.

— Oil and Gas Engineering Services

Hydraulic Services

DTY services Hydraulics offers a vast range of hydraulic products, site engineering and MRO services cater for heave compensation tensioner system for riser or pipe laying system, deck machinery, offshore crane, hydraulic grab, oil cooler, hydraulic power pack and hydraulic driven equipment. As part of the hydraulic services, the following are our capabilities:

- Commissioning

- Site Inspection

- Design, Manufacture and Installation of Hydraulic Circuits

- Maintenance, Repair and Overhaul

- Upgrades or Modification

— Oil and Gas Engineering Services

Fabrication and Fittings

We provide fabrication and fittings services according to your system or module requirement. It also has to be accompanied by testing that ensures any of the products manufactured for a particular purpose will be able to handle the stresses and strains.

— Oil and Gas Engineering Services

Maintenance, Repair and Operations

We provide service support to minimize downtime by providing versatile repair of o-ring, complex proportional control valves, variable displacement pump, motor, hydraulic machinery, cylinders/rams, accumulators. As long as its hydraulics related, we can fix it unless beyond practicable operations. We provide quick and easy solutions as follows:

- External or internal visual inspection on reparability and failure cause

- Repair or manufacture of custom and standard hydraulic cylinders to specification

- Troubleshooting and faultfinding

- Maintenance of steel and stainless steel tubing for all hydraulic systems

— Oil and Gas Engineering Services

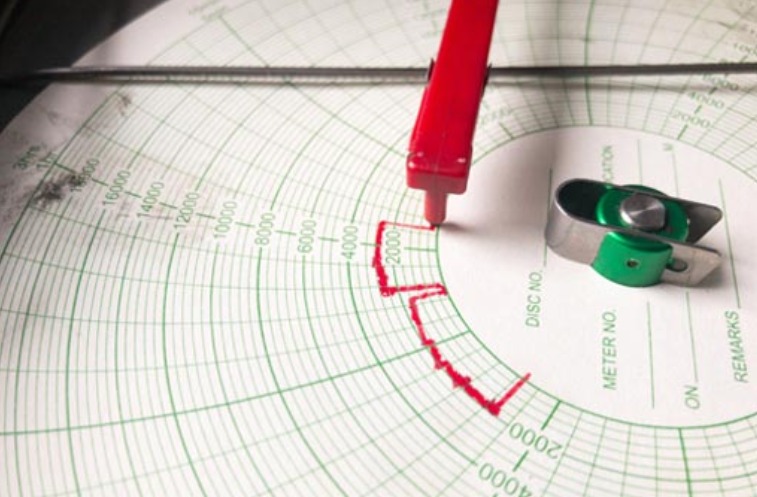

Flushing

We provide chemical flushing and hot oil flushing according to customers’ system requirements. Fluid Analysis report will be provided for every cleanliness result depending on system requirements if required.

- ISO 4406

- NAS 1638

- SAE AS 4059

Our equipment comes with a full range of interchangeable filter elements (as fine as 3µ to 10µ) that will cater to maintain oil cleanliness and integrity of the piping system.

— Oil and Gas Engineering Services

Pressure Test

Our pressure test ensures pipelines or vessels are leakage free and comply with international safety standards or as per defined specifications. The test involves filling the system with testing medium, which is then pressurized to a specified pressure and hold for a period of duration depending on its standards or specification. All procedures are documented in the operation manual and equipment certificates are included. We provide quick and easy solutions as follows:

— Oil and Gas Engineering Services

Pipeline Services

DTY services pipeline services include pre-commissioning, commissioning, regular maintenance and shutdown services. We understand the criticality of piping to be undertaken and have the following within the scope of works:

Chemical Cleaning

When compared to mechanical cleaning methods, chemical cleaning process reduces downtime, reduce exposure to toxic materials and environmental hazards.

The objective of chemical cleaning is to remove unwanted foreign material inside the pipeline or system. Key concerns are to remove weld scale, grease & oil, mill scale, corrosion products, sand, dirt, temporary protective coatings and other undesirable debris.

We identify the key process equipment and solvents required for the cleaning process based on the type of pipeline or system material being used. Subsequently, we generate the project work scope required to conduct the task with a cost analysis benefit and execution plan

Oil Flushing

The primary objective for oil flushing is to reduce the potential for premature failure.

The process removes contaminants such as water, rust, loose scale, weld slag and dirt from the system with preoperational cleaning method first before processing with oil flushing procedure. Majority of hydraulic system failure relates to improper or poor fluid conditions.

Leak Testing (Nitrogen)

To comply with the stringent safety standards, all leaks need to be located and remedial actions to be arrested.

In order to detect even the smallest leaks, the most effective method is to use Nitrogen as a traceable gas as it is mono-atomic. The fact that it is an inert makes Nitrogen ideal for leak detection purposes as it is not affected by the presence of other gas and contaminants.

In preparation for the test, the flange connections are taped in order to encapsulate the space between the flanges, thus capturing any escaping gas resulting from a leak in the encapsulated space. The nitrogen is injected into the system or installation until the required working pressure is achieved

Hydro jetting

Hydro jetting services which are also known as high pressure water jetting service. The process uses highly pressurized water from 3,000psi to 40,000psi to clean and remove any unwanted construction debris, rust, mill-scale from newly installed pipeline and even cold cut materials in any open or enclosed areas that are difficult to access. At 4,000psi, hydro jetting systems has the power to burst open the toughest blockages and at the same time scours the full diameter of the pipe, flushing debris, leaving a clear surface.

These techniques have been used in practically every industry especially in cleaning of internal and external walls of pipelines, heat exchanger, boiler tubes, air fin coolers, tank, vessel, drainage etc. Hydro jetting cuts away clogs and slugs to prepare surface materials for repainting and removes grease build-up, rust, rubber, chemicals or other heavy build up without causing damage to the surface below it

Pressure Testing (Hydrostatic / Pneumatic)

Pressure testing ensures that pipelines or vessels are leakage free and complies with international safety standards or as per defined specifications.

The test involves filling the system with air, nitrogen, water, glycol or hydraulic oil, which is then pressurized to a specified pressure and hold for a period of duration depending on its standards or specification. The procedures are documented in the operation manual and equipment certificates are included.

Flange Management (Bolt Tensioning and Torqueing)

Specialized bolting equipment used for bolt tensioning and torqueing ensure the correct controlled bolt load are achieved for all bolted joints during construction and for all subsequent maintenance & repair operations.

We provide the following services:

- Full joint survey

- Calculated and Controlled Bolt Tensioning / Torqueing

— Oil and Gas Engineering Services

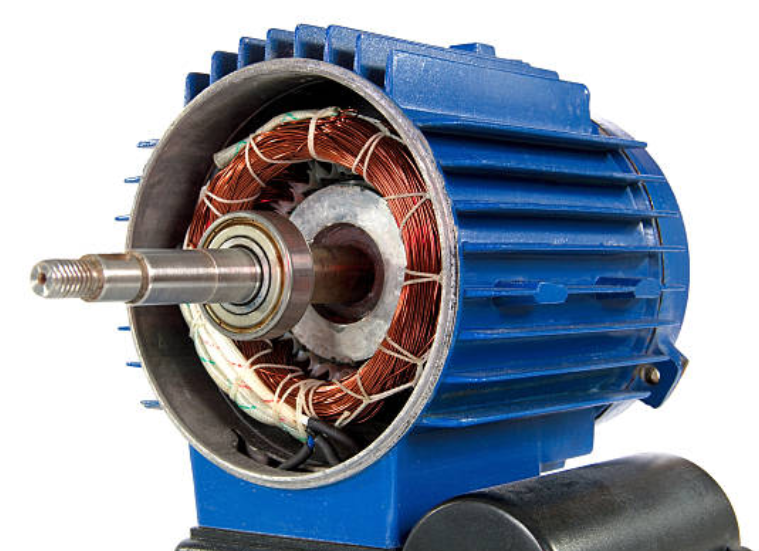

Electrical

DTY Services Electrical provides seamless connectivity solutions for Offshore electrical systems such as Cable Laying / Installation / Termination, Cable Control & Instrumentation systems as well as repair of all types of electrical systems. We are able to provide a broad spectrum of services which includes the following:

- Electrical engineering drawing

- System analysis & design

- Production

- Installation

- Commissioning

- Maintenance and Repair

The services can be carried out at our facility or at your designated shipyards, industrial plants, anchorages, ports, wharves, jetties and onboard vessels such as rigs, FPSOs, barges, vessels, oil tankers etc.

— Oil and Gas Engineering Services

Steel Fabrication

DTY Services Steel Fabrication offers Steel and Pipeline fabrication, engineering and repair services for steel structures, process line, platforms, skids, modules, precision equipment and machinery parts for Offshore and Marine Industries according to classification requirements (e.g. ABS, DNV, LR, BV, NK, GL etc). Our services include: We are able to provide a broad spectrum of services which includes the following:

- Site inspection for repair or modification

- Engineering and fabrication

- 3rd party inspection

- Nondestructive testing (NDT)

We have the following documents according to above-mentioned standards:

Welding Procedure Specification (WPS)

This documents a list of the base metal, thickness, welder settings and 20 other parameters being identified.

Procedure Qualification Record (PQR)

This documents our welders’ ability to produce weld which meet prescribed standards.

Welder Qualification Test Record (WQTR)

This documents the welding results performed by our welders for their ability to work within the specified WPS.

International Standards

All our welders are highly trained and qualified and maintain strict international standards based on our customers’ specifications.

We provide the following in-house welding operations:

- MMAW (Manual Metal Arc Welding)

- GTAW (Gas Tungsten Arc Welding)

- GMAW (Gas Metal Arc Welding)

- SAW (Submerged Arc Welding)

Our welding procedures follow strictly to international standards like AWS D1.1, ASME Sec IX, ASME B31.3 and BS EN 288 used for stainless steel, carbon steel, alloy steel, various exotic materials like Inconel, Monel, cupronickel and duplex stainless steel.

Hear from our clients

DTY Services has been an invaluable partner in our project's success. Their unwavering commitment to quality and safety, combined with their seamless integration of services, has truly set them apart in the industry.

- John Smith, Project Manager, Apex Constructions

The expertise and professionalism displayed by DTY Services have been instrumental in the timely and efficient completion of our complex engineering project. Their attention to detail and proactive approach have exceeded our expectations.

- Sarah Johnson, Operations Director, OceanTech Solutions

We have collaborated with several engineering firms, but none have matched the dedication and technical prowess exhibited by the team at DTY Services. Their ability to provide innovative solutions while prioritizing cost-effectiveness has been a game-changer for our business.